DDK Define Deliver Sustain | A Fully Integrated Project Delivery Model

5 October 2022

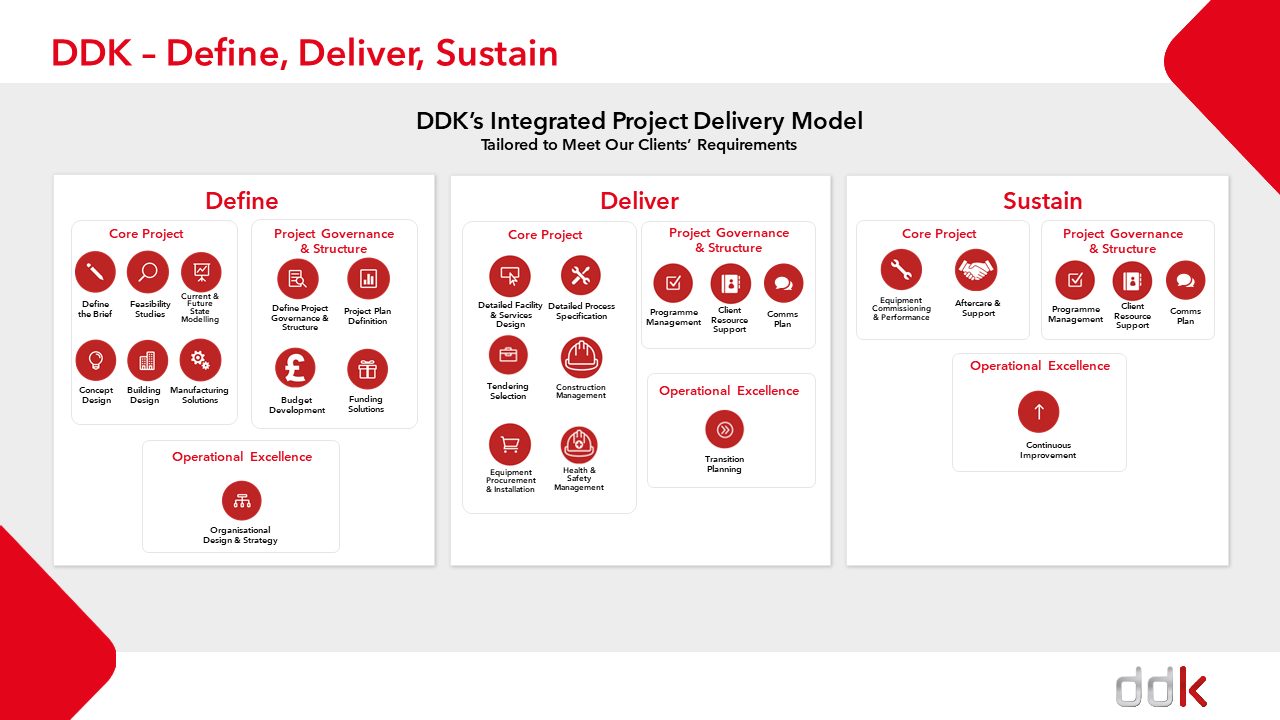

DDK’s integrated project delivery model, Define Deliver Sustain, coupled with our breadth and depth of industry experience and expertise, provides a comprehensive and adaptable structure to deliver clients’ capital project requirements.

While manufacturing facility design and construction by DDK is at the heart of the model, this can be tailored to provide our clients with competent and experienced resource to support them through the design, specification, procurement, installation and commissioning of new production lines, either as part of overall design and delivery of a facility, or in isolation.

CASE STUDY

The Context

A DDK client secured new business for the supply of a new product range to a retailer, requiring the establishment of a new manufacturing line to launch and deliver the product range (the confidentiality of the client, the product range and the retailer are respected here).

The client recognised that they did not possess in-house resource with the relevant experience to lead and deliver this project. DDK were engaged to provide an Engineering Project Manager to define and deliver the project.

Following a detailed definition phase, the project scope for the manufacturing line identified the following key process steps:

- Automated in-bound ingredient handling (temperature controlled)

- Automatic product filling, including sealing and lid application

- Fully automated end of line packaging involving case erection, packing and palletising, inclusive of associated checkweigh, metal detection and labelling (all integrated with the site’s existing data acquisition and recording system)

- The line was required to handle a range of product sizes (3x) and associated packaging sizes

- Modifications to the existing site’s building fabric and engineering services were also required to receive the new line

The Solution

Through a structured ongoing review process through the life of the project, working closely with and engaging the client’s project team across the disciplines of Operations, Engineering, Technical, Commercial and Procurement, the assigned DDK Engineering Project Manager led this project from initial concept through to successful launch.

Within this dedicated role, the DDK Engineering Project Manager led and delivered the following:

- Project management and communications in terms of regular review with the Project Team and wider client business progress reporting, including the retailer

- Definition of the manufacturing line’s scope, deliverables and layout

- Research and identification of equipment vendors – including specification, tendering, preferred selection and supply contract application

- Design of all aspects of product packaging (primary, secondary and tertiary)

- Identification and planning of the manufacturing line’s resourcing requirements, including a recruitment and training plan

- Compilation, submission and approval of the client’s CapEx documentation

- Procurement and installation of all equipment elements of the manufacturing line – including associated site engineering services and building fabric upgrades and reconfiguration

- Pre-production performance trials – including operative engagement and training, and associated product validations and sign-off (client internal and with retailer)

- A detailed phased product launch plan

The Result

The line was delivered safely, achieving specification in terms of performance and efficiencies, achieved the required launch date, and delivered the project within approved CapEx budget.

DDK continue dialogue with this client in preparation for future specific capital projects and wider capital programme management.